Mass Engineered Timber (MET) + PB Approach

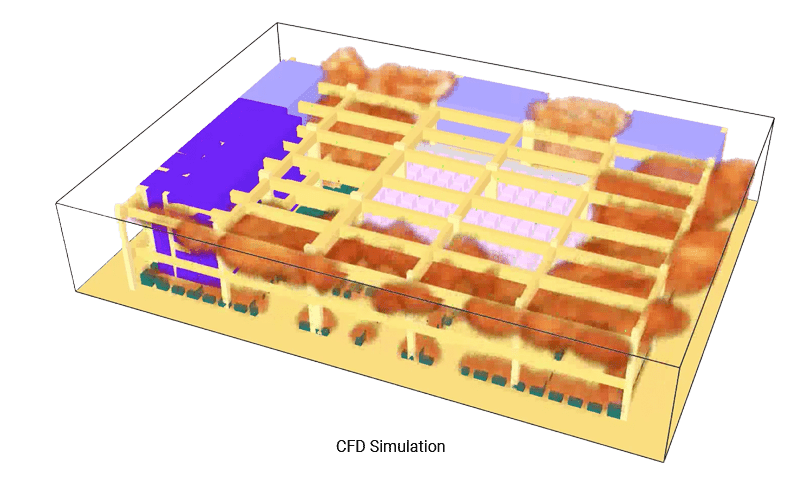

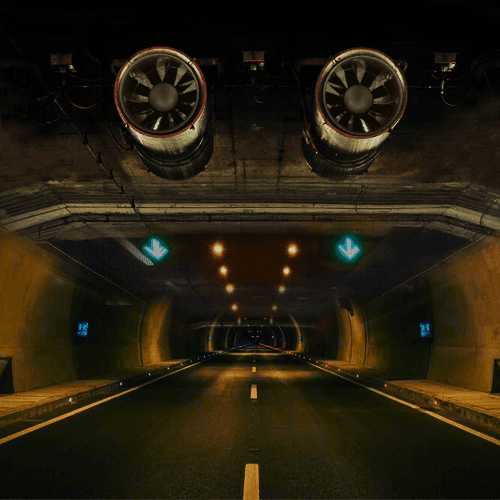

Timber charring can achieve the same level of fire resistance as other building materials

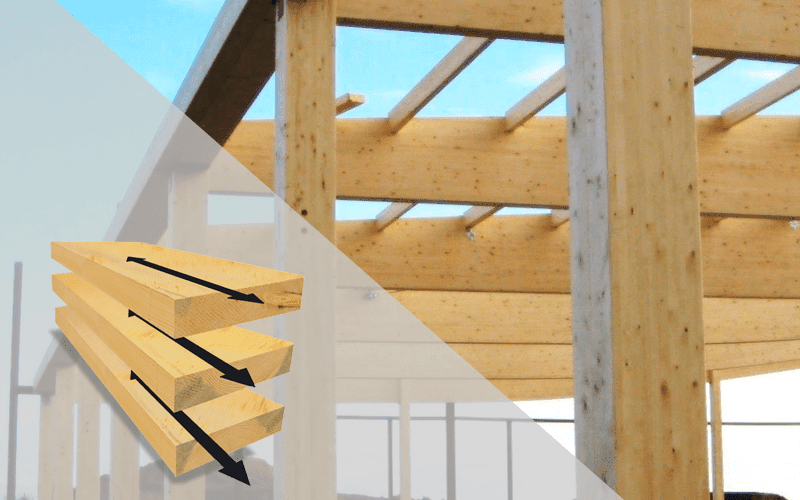

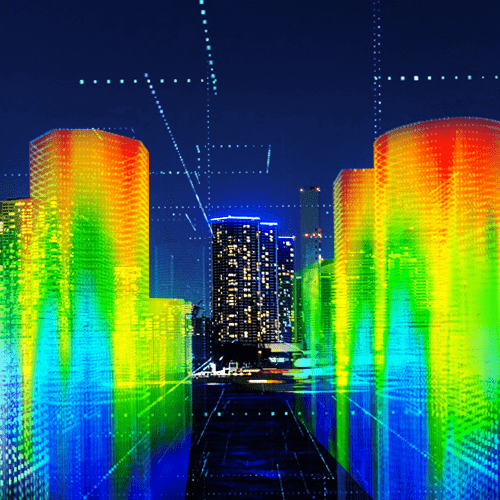

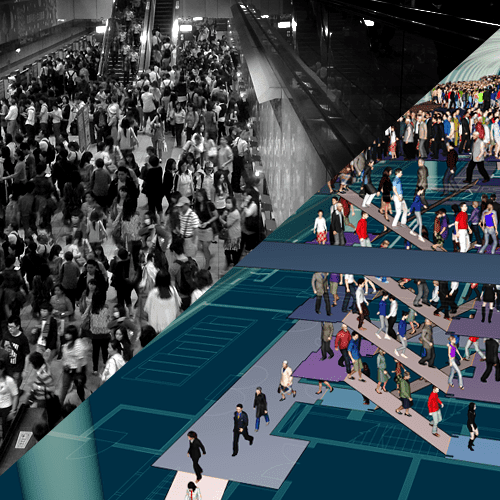

Mass Engineered Timber (MET) is a building material growing in popularity in Singapore, and comprises engineered wood products with multiple benefits. MET is environmentally sustainable, lightweight and durable, and is highly fire-resistant. As a form of DfMA (Design for Manufacturing and Assembly) technology, MET allows for modular construction through offsite construction, facilitating custom designs and greater on-site productivity through faster assembly.

Mass Engineered Timber is primarily manufactured from sustainable softwood species in Europe. It comprises both CLT (Cross Laminated Timber) and Glulam (Glue Laminated Timber), for use in the construction of various types of developments, such as commercial, infrastructure and institutional buildings.

Mass Engineered Timber has garnered rapid acceptance, both in Singapore and across the globe for constructing both low and medium-rise buildings. It is loved for its high structural integrity as well as a classy aesthetic. As an engineered product, it can also be crafted to specific design requirements, ensuring better quality control through precise and automated manufacturing processes. It is also prefabricated offsite, achieving significant time savings as well as reduced dust and noise when commencing onsite construction.

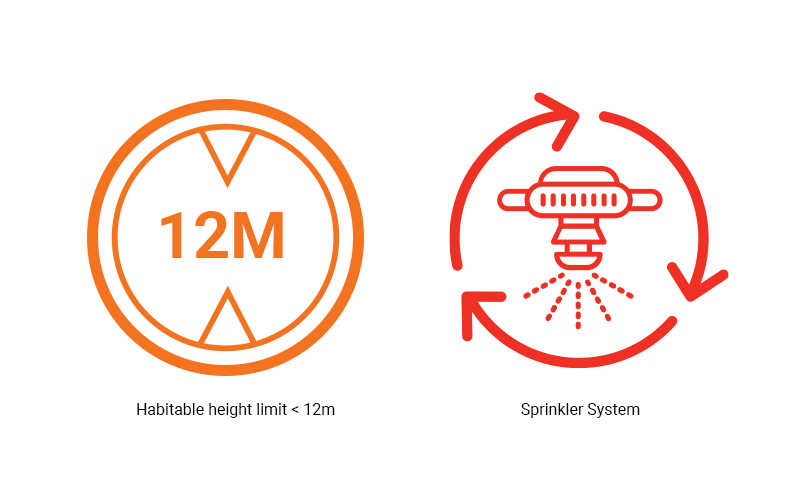

In addition, Mass Engineered Timber offers respectable fire resistance, making it ideal for commercial construction in Singapore, which is why it forms a key component of SHEVS IFT’s fire safety engineering designs.

Find out more >> SCDF Fire Code 2023 – Clause 9.9.5 Engineered timber building construction

Contact Us

Follow us on: